Mock to Magnificent

(without marking)

Pressure Marking Industrials

Brass to mock-up Barbell

Amazon: 1.6mm (14g) Copper Wire

Ebay: 1.6mm (14g) Copper Wire

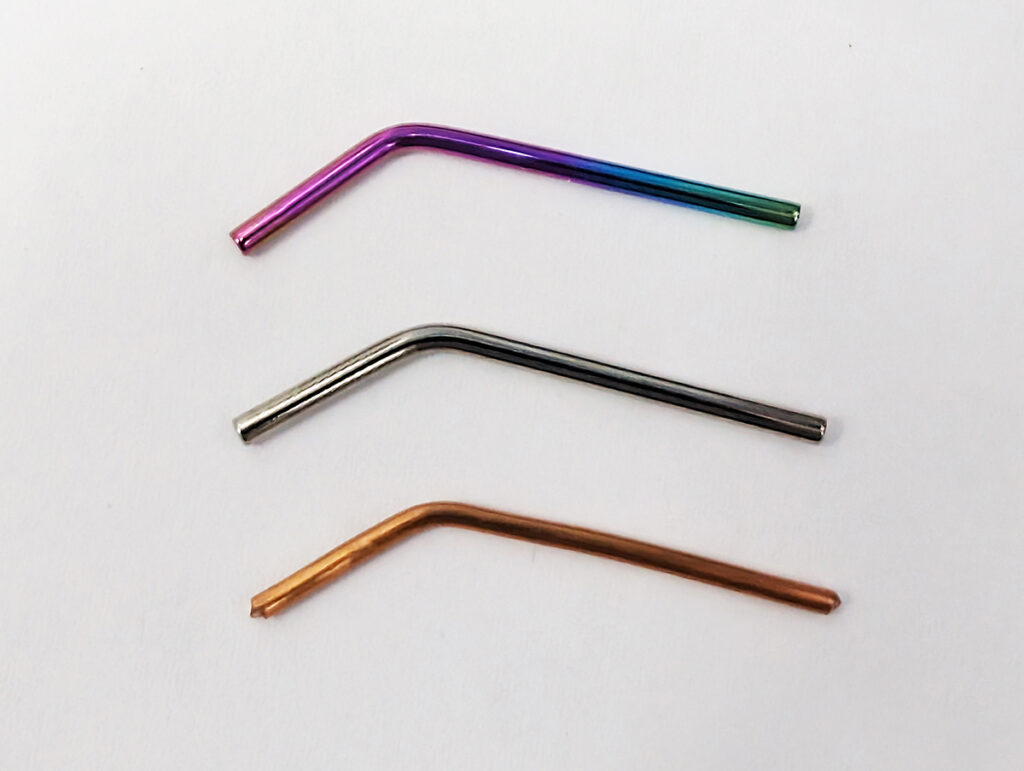

Brass -> Bent (unpolished) -> Polished (and anodised)

Polishing is important (SafePiercing.org.au)

| Image | Condition | Finish (Ra mμ) | Acceptable to use |

| Factory hand polish | 0.04 | Yes | |

| Bent at 90° (no re-polish) | 0.17 | No | |

| Bent at 90° (re-polished by hand) | 0.03 | Yes |

Direct metal-to-metal contact can cause marring, gouges and scratches on the material’s surface, even when utilising brass-lined tools. Padding your tools with gauze, silicone socks, or cohesive bandage will significantly help to reduce deformations or scratching during installation or removal of jewellery.

Bending metals (like creating a nostril screw or modifying an industrial barbell) will cause dislocation of the surface finish walls. This creates a complex three-dimensional web of crystal defects in the metal, which can be seen as dulling with the naked eye, especially in harder materials like titanium.

Tension and compression will make the surface finish unacceptable for a piercing and requires hand polishing.

Polishing Wheel

Go

Amazon (USA – 110v): Bench Buffer Polisher

Needle Blanks

Clickerino: Blanks blanks blanks

ISLLC: Needle Blanks